Price

vr-one crankcase reed valve

Code: 5717230 Looking for a replacement?Description

VR-One REED VALVE

The VR-One is for power purists, for those seeking to push their Vespa to the limit, but not only this.

It has the same assembly characteristics in the body as the V-One and the same possibilities of cylinder housing

thanks to the revised fluid dynamics of the crank chamber, to the drilling of the studs and to the same accessories

supplied with the V-One (except for the mixer pin).

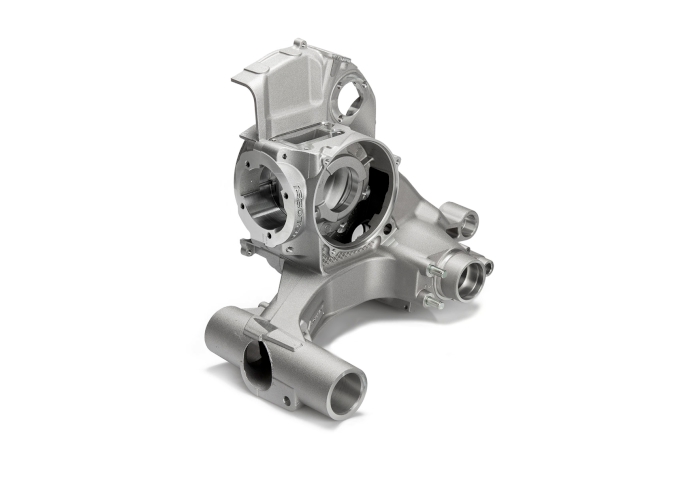

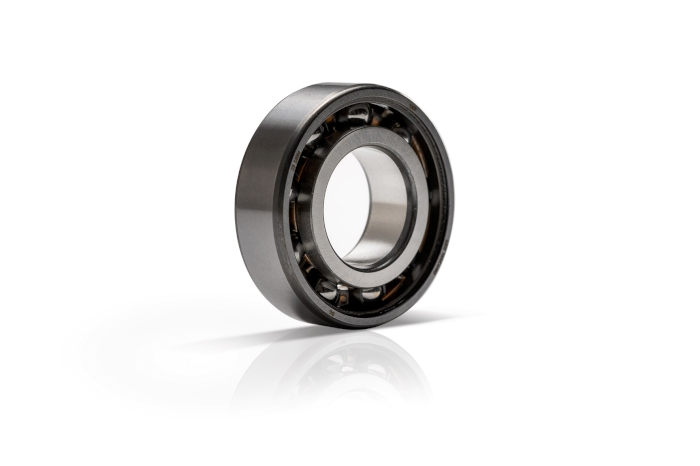

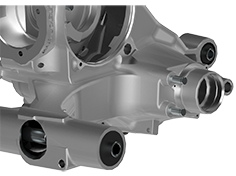

This crankcase has been designed to withstand higher powers and is therefore supplied with main ball bearings

on the flywheel side Ø25xØ52x15 and on the drive side Ø25xØ62x12, which remove the roller bearings and offer

greater radial load tolerance capacity and an additional resistance to axial loads, not envisaged with the original roller

bearings. Dedicated seals are also supplied.

The greater resistance to stress due to the crank drive means the crankcase is perfect

to be assembled with our cylinders but above all with the 3118599 single-ring MHR kit (60 stroke). The natural combination for this configuration is with the Malossi engine shaft with full shoulders, 60 stroke, item 5316176, supplied with correct

balancing and perfect for reed valve supply envisaged for the new VR-One.

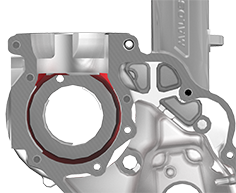

Reed valve supply

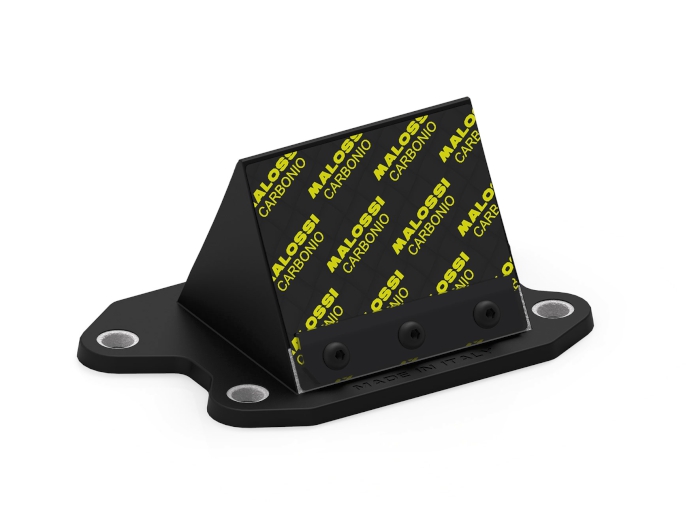

Here lies the major innovation and the sporty orientation of the crankcase, now powered with a system that is ENTIRELY

SUPPLIED with the reed valve assembly that, thanks also to the new high quality carbon fibre reeds, ensures an

increase in power across all the operating speeds and concurrently allows achievement of the highest speeds.

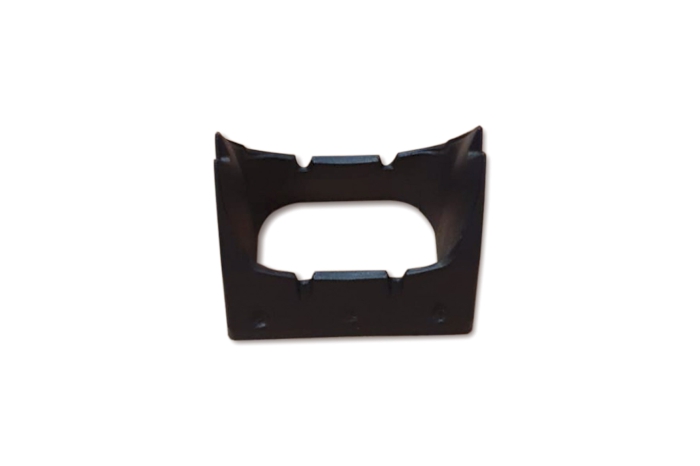

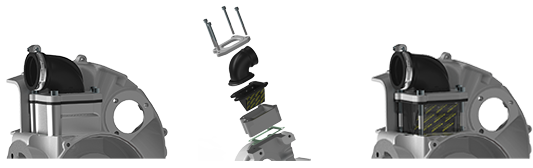

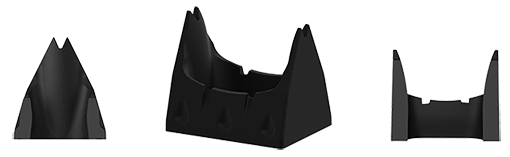

The assembly consists of a die-cast valve seat, coupled to the crankcase plane with a seal guaranteed by a dedicated

gasket, and a completely new reed valve fitted with a multiple-profile diffuser, specially designed with fluid dynamic

simulation programs. The assembly also includes a particular configuration of the side walls that are able both to

eliminate part of the turbulences, which normally occur when the petrol-air mixture passes through the diffusers, and

at the same time directs the charge in the correct direction, once the reeds have been opened.

The supply manifold, designed according to the X360 technology used in our competitions, consists of a die-cast flange connected to a Viton coupling through the tightening of a profiled lip, which guarantees a perfect hermetic seal, and at the same time turns the coupling in the direction desired by the user thereby positioning the system perfectly according to the shape of the vehicle.

The pipe has an inlet diameter of 30mm. The ideal combination is the Dell’Orto PHBH 30 carburettor (not supplied).

Malossi decided that it was time to break with the past to create an iconic component for an equally iconic vehicle

such as the Vespa PX200E! Taking advantage of all the technology and knowledge acquired along the roads and tracks

around the world, Malossi has developed the new V-One and VR-One crankcases.

The design, the study, the research and the production of these crankcases are the ways in which Malossi aims to pay

homage to the fans of these vehicles.

The two models allow mechanics, restorers and, more in general, all owners of a Vespa PX200E to choose the

modification route that best suits their needs:

- The amateur, the restorer, the traveller are all looking for a component that is able to perfectly replace the original one, which does not require any modification to the vehicle and which offers maximum choice in terms of components . The V-One SPORT crankcase will be compatible both with traditional components and with the main items currently on the market

- The mechanic in search of maximum performance, of the best internal fluid dynamics and of the highest possibility of engine development will be able to purchase the VR-One MHR crankcase

TECHNICAL FEATURES

Fully made in ITALY

The technical and technological advancement of Malossi is the greatest strength of our products, the reason why we are convinced we have created one of the best crankcases that has ever been produced.

Strengths

An innovative twist is evident in every square millimetre of the crankcase that is clearly obvious to even the most

inexperienced mechanics.

The gravity permanent mold casting , which differentiates these crankcases from the original models, obtained,

instead, with a die-casting process, combined with the use of modern shell moulding cores, results in improved

internal shaping, created with the utmost precision.

Using gravity casting we were able to strategically increase the sections in the most stressed areas and to subject

the crankcases to an enhancement treatment after casting, thus obtaining an extremely high mechanical resistance.

These products are made of a high quality Al Si 7 Mg aluminium alloy (EN AB and AC 42000) containing in the appropriate

quantities: Silicon, to increase the mechanical resistance, Manganese, for improved resilience and corrosion resistance

and also Copper and Magnesium, to improve overall workability.

The processing of the crankcases is performed entirely at our workshop using CAD / CAM process and takes place

within high-precision CNC machining centres. All the support and sealing surfaces have been worked with diamond

tools that are able to guarantee very low surface roughness values and virtually perfect couplings.

Advantages

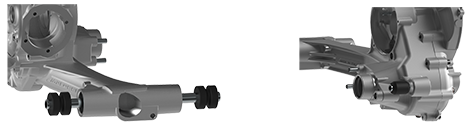

Both crankcases share a series of basic characteristics such as, for example, the front arm reinforced with tension discharge ribbing and sections with profile calculated to allow the correct flow and channelling of stresses and to guarantee a higher level of resistance.

Both models include rods for the brake shoes, which are installed directly at the company with presses that are able to apply the forces necessary to create the couplings required by our designers.

In addition to the brake blocks, the crankcases are supplied with the M7 studs necessary for mounting of the gear selector.

Lastly, all versions include the original electric starter, whose actuator can be mounted in the relevant plane formed in the volute.

Assembly of the crankcase on the vehicle does not require the purchase of any additional component, in fact both versions are fitted both with front Silent Block in the arm connecting to the body and with a rear anti-vibration device connected to the shock absorber.

Fluid dynamics have finally been implemented! As our standard models are fitted with transfer ports that are adequately profiled and sized for perfect coupling to our Ø68.5 cylinders, without however excluding the possibility of mounting other thermal groups and even also offering an increase in performance with the latter, mechanics are consequently not required to work the crankcases to assemble higher performing cylinders. M8 studs for cylinder mounting are also included in the package!

Thanks to the interventions listed, achieving higher powers is no longer a problem. Even the usual problem of oil leakage from the crankcase has been resolved through:

- Increasing of the walls of the pump crankcase, which also further contributes to the mechanical resistance of the crankcase

- The use of M8 studs instead of the original M7 ones

- Extremely precise processing of the sealing surfaces. We removed the crankcase gasket, which deteriorated and became the main reason for oil leakage. Now the crankcases are perfectly combined and sealed using gasket paste, resistant even at the highest operating temperatures.

But we didn’t stop there! After years of assembling and disassembling original crankcases, working them and

trying out thousands and thousands of solutions with the aim of proposing constantly updated components, we

encountered first-hand inefficiencies and problems that we analysed to then propose our solutions: this is the case

of the crankcase clamping system which in the original components is created with the classic screw-nut system,

notoriously inconvenient and not particularly user-friendly.

A vehicle that is so precious deserves the best possible maintenance and this involves the need to assemble and

disassemble the various components to replace them or even just to check correct operation, servicing them when

necessary. Anyone who has ever had to deal with the original crankcases without disconnecting the block from the

vehicle will have undoubtedly encountered difficulties in handling the components that compose the block given the

uncomfortable and unreachable position of the nuts which, once unscrewed, tend to fall onto the ground and become

lost somewhere. Our solution is as simple as it is sophisticated: dispense with the nuts!

Creating threads in the left crankcase (or transmission crankcase) and seats in the right side (or ignition crankcase)

we removed the need to have nuts to tighten the two components.

To prevent the screw from being accidentally struck as well as avoiding damage during operation, with the risk of

damaging the threading, where possible we have created seats on the right side that allow complete recessing of the

screws, thereby positioning them away from any danger.

Products reserved exclusively for racing in specifically designed locations according to the provisions of the competent sporting authorities. We disclaim all liability for improper use

Compatible brands and models

| Brand | Model |

|---|---|

| VESPA | VESPA PX E 200 2T |

Components and Spare Parts

Accessories

| Product name | Code | Price | |

|---|---|---|---|

| mhr intake rubber for ø 34 carburettors with connection ø 39 | 1317660b | 42.35€ | Cart |

Download